Assement of Environmental Damage by Polyacrylamides

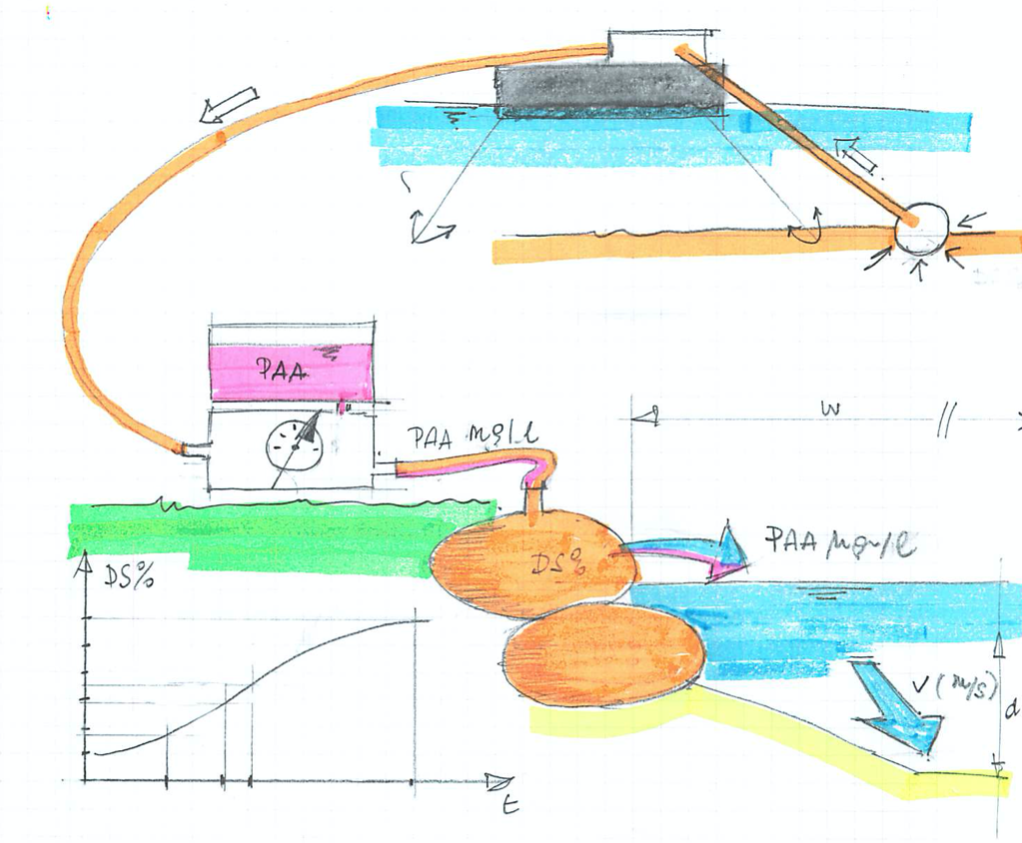

Geotextile tubes

High strength permeable filter fabrics with unique designed retention properties are fabricated into geotextile tubes. Geotextile tubes can be filled with fine grain sludge, hazardous contaminated soils or dredged waste materials. The filter fabrics' unique weave and fabrication creates small pores that confine the fine fractions of the contaminated material.

Dewatering

Excess water drains from the geotextile tube through the small pores in the filter fabric, resulting in effective dewatering and efficient volume reduction of the contained material. This reduction of volume allows for the repeated filling of the geotextile tube. In many cases the decanted water is of a quality that can be returned to native waterways or can be used for re-use.

Consolidation

After the final cycle of filling and dewatering, the retained fine grain materials can continue to consolidate by desiccation, because the residual water vapour escapes through the filter fabric. This results in the most cost effective residue state for disposal or re-use

Impact of Polyacrylamides on the environment

Texion commissioned a risk analysis for the aquatic ecosystem in case polyacrylamide flocculants are used for the dewatering of sludge using geotextile tubes (e.g. dredged mud) to Vito, an independent research institute. The study was made for 3 types of polyacrylamide flocculants: DREWFLOC 470 (6% cationic polymer), DREWFLOC 413 and PRAESTOL 610 BC (both 10% cationic polymer) from producer Ashland. The results of the outcome of the report are only valid for these specific products. This calculation module of the Texion Applet makes it possible to make an assessment of the conditions under which geotextile tubes and the 3 specific polymers can be used in (1) and open system leaving the effluent draining free and (2) where a closed (watertight, sealed) system with collection of the effluent is necessary.

Humic acids in surface water

Humic acid is a principal component of humic substances, which are the major organic constituents of soil (humus), peat, coal, many upland streams, dystrophic lakes, and ocean water. It is produced by biodegradation of dead organic matter. The Vito report provides default values for different types of water.

Suspended solids in surface water

Default value is 25. Suspended solids are important as pollutants and pathogens are carried on the surface of particles. The smaller the particle size, the greater the total surface area per unit mass of particle, and so the higher the pollutant load that is likely to be carried. The Vito report provides default values for different types of water: lakes, brooks, canals, and rivers.

Impact zone, depth and width

The impact zone does not have necessarily the geometry of the section of the adjacent watercourse.

Total duration of the dewatering process

The time, starting from the pumping of the sludge into the geotextile tubes, to the moment where the final volume reduction is obtained. During this period most of the water will have drained from the geotextile tube.

Dry solids after dewatering

The objective of dewatering is to obtain a, as high as possible, percentage of dry solids (DS) in the remaining soil in the geotextile tube . Typical values are 25% for organic sludge, 75% for sandy materials.