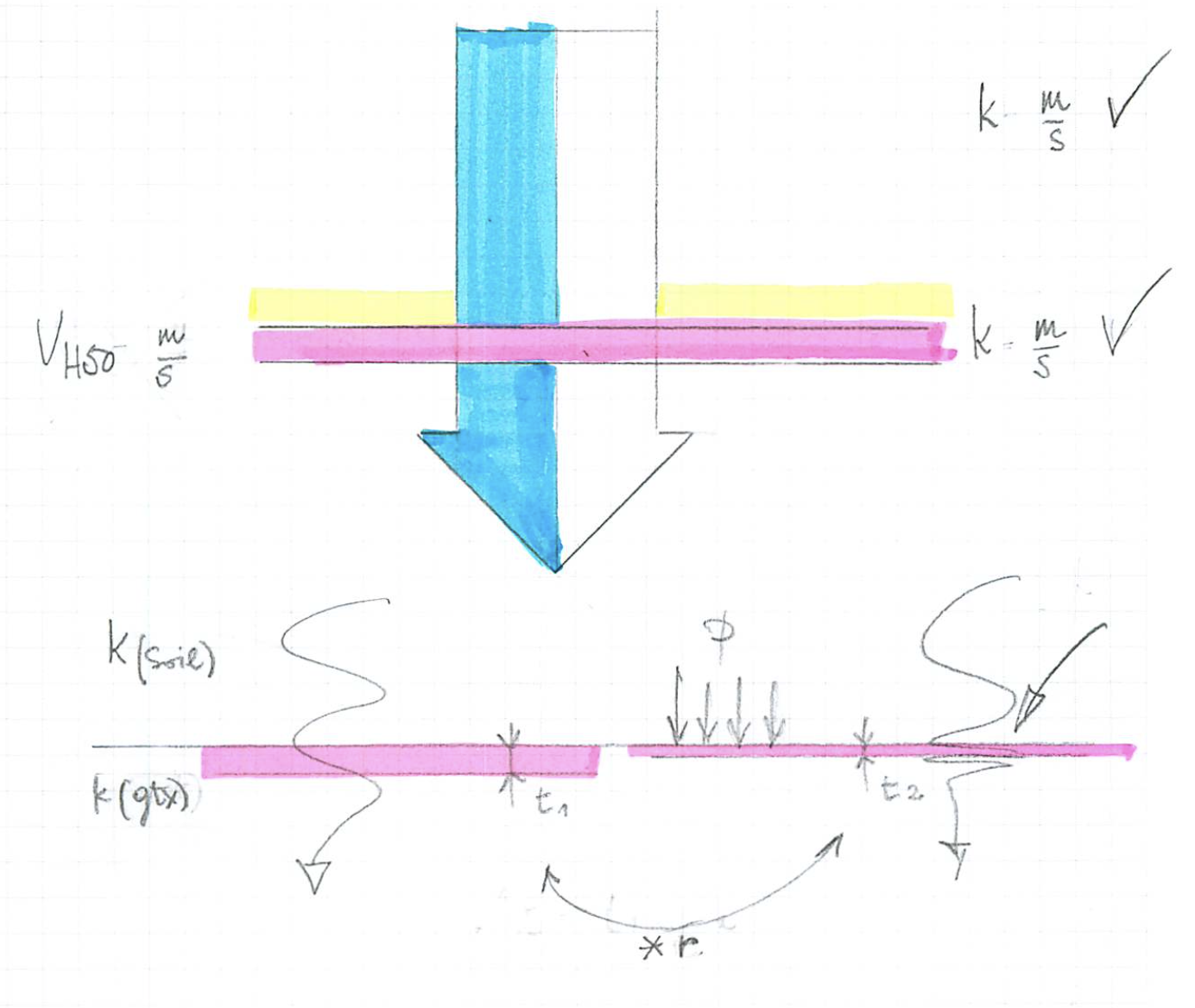

Reconvert from flow Q to velocity index V(H50) (following EN IS0 11058)

Calculation method

The best way to understand permeability is to think of it as a resistance to water flow. It is quantified by giving it a number called the Coefficient of Permeability (k) in m/s. The larger the number k, the smaller the resistance. When a soil has a high permeability, it really means that it has a low resistance to water passing through it. The same applies to a geotextile. A high permeability means that the geotextiles has a low resistance to water flowing through it. Notice the difference between the term ‘Permeability’ (l/m2/s) and ‘Permeability Coefficient’ (m/s). For soils the resistance to water flow is expressed as k(soil) in m/s.

The water permeability of a geotextile is given in EN ISO 11058 as Velocity Index (VH50) in m/s. This dimension is the result of the simplification of l/m/s, in which l = m310-3, which is mathematically correct, but meaningless for the user. Another danger is that the outcome in m/s has the same dimension as a Permeability Coefficient, which it is not. The Texion Applet allows reconverting the Velocity Index from a geotextile, into the Permeability Coefficient of the same geotextile, by introducing the thickness (t).

When installed e.g. underneath a road, the thickness of a geotextile will be reduced. This means that the thickness in mm under 2kPa, given in most spec sheets, is not valid any more. Therefore a coefficient of reduction in thickness between 1 and 4 has to be foreseen. For woven geotextiles the thickness will not change much (r = 1), the thickness of nonwovens can be reduced dramatically under high loads.

Over time, the water permeability of the geotextile will reduce, because soil particles will block openings. This can result in blinding, clogging and blocking.

Design should foresee a high factor of safety between the permeability coefficients of the soil and the geotextile; a factor of 10 is ideal.

Water permeability and retention of soil particles

Those two properties are in conflict to each other. The greater the openings, the more water flows through, but the fewer particles are retained. An optimum should be sought to reconcile the two conditions.

If there is a choice to be made between water permeability and retention of soil particles, it is the experience of Texion that an 090, that is theoretically too large, can be chosen. The passage of small soil particles, through the geotextile, allows a natural filter to build up. This graded structure of particles ensures that blinding, clogging and blocking will be avoided.